| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Qunxingwang

Place of Origin : Shenzhen

MOQ : 1 set

Price : negotiable

Payment Terms : T/T/ Western Union/ cash

Supply Ability : 30 sets/month

Delivery Time : 3-8 weeks

Packaging Details : standard export wooden case or according to customers' requirements.

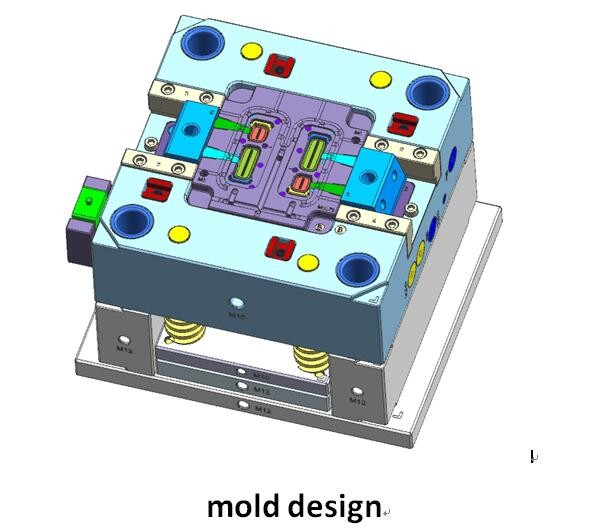

shaping mode : plastic injection mould

product material : plastic

plastic material : ABS, PP, PC, PE, PA, PU, PS, POM, PVC, PMMA, Rubber, etc

mould material : P20, 2738, 2344, 2316, S7,S136, H13, 718H, S50C, NAK80, 40Cr, 60#, 45#, 5crNiMo

mould standard : HASCO, DME , LKM

runner type : hot runner , cold runner

runner brand : Hasco, Synventive , Yodu, Mold master

method : injection

color : clear

ejector system : ejector pin

gate type : sub gate, pin-point gate, banana gate

mould design software : Ug, AotoCAD,Proe

transportation : by sea , by air or according to customer's requirements

customized design plastic cups/plastic cup OEM injection

mould/plastic cup injection parts/plastic cup

Description:

| Surface treamment | Texturing,polished | ||||||||

| De-mold Type | Automatic eject | ||||||||

| Mold Base | LKM, | ||||||||

| Mold Material | 2344 | ||||||||

| Mould Cavity | 1 | ||||||||

| Sprue Gate | Hot runner, Cold runner , Submarine gate | ||||||||

| Design Software | UG,PROE,CAD | ||||||||

| Plastic Material | PP, PC, PS, PAG, POM, PE, PU, PVC, ABS, PMMA | ||||||||

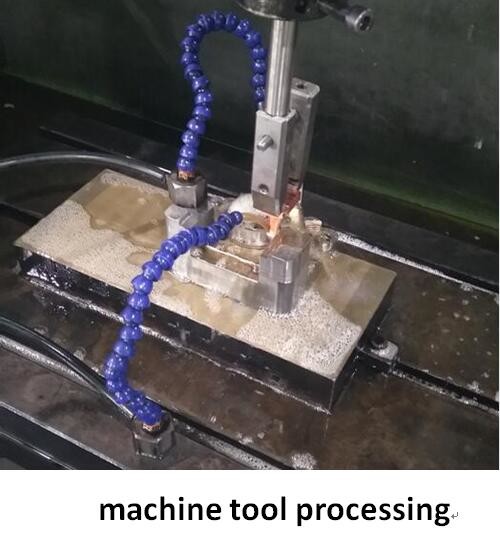

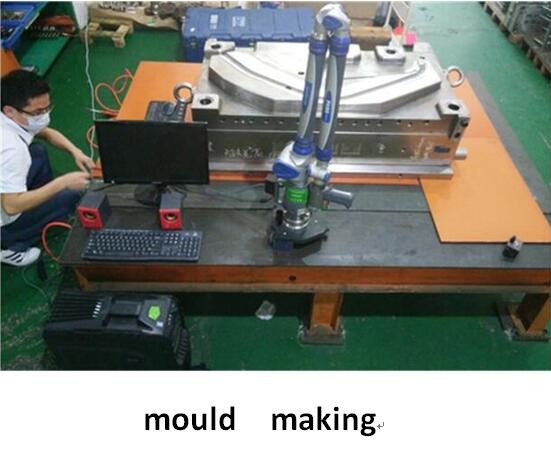

| Main processing equipment | CNC, EDM, Milling machine, Grinding machine, Injection machine | ||||||||

| Moild Life | 300000-1000000 shots | ||||||||

| Cavity/core steel | NAK80,S136,2316,2738,H13,S7,718H,2344 | ||||||||

| Steel hardness | HRC48-52 | ||||||||

| Cycle time | 40 seconds | ||||||||

| Design time | 3 days | ||||||||

| Specification | As your requirements | ||||||||

| OEM order | Greatly welcome | ||||||||

Our advantages:

1. We are efficient in quotation and new project response.

2. More than 10 years manufactory and export experience let us know customers' demands, just tell us what you

need.

3. We have professional design team, we know very well in processing technique or plastic, steel&stainless steel,

and general mechanical.

4. We know how to reduce cost/save money for you, we will tell you how to adjust/change your design, not only to

save cost but also make the products better.

5. We will keep secret for your new idea, and we can sing"confidentiality agreement" with you.

6. We take in charge of all the parts/accessories, if any quality problem, we are the one has responsibility on it.

FAQ:

Which kind information need for quotation in Qunxingwang company?

1, Sample photo with size or 2D/3D design.

2, Cavity quantity.

3, Runner type, cold or hot.

4, Mould steel type,P20, 718, 2738,H13,S136,2316,an so on.

5, Injection machine parameter or plate size(tie rod distance).

Why choose us?

1 ) World class plastic parts

We provide our customers with all types of plastic mold parts with world class quality.

2 ) Genuine products with excellent Quality

We have always proved the 100% quality products it provides with genuine intent.

3 ) After sales service and technical assistance

The company provides after sales service and technical assistance as perthe customer’s requirement and

needs.

4 ) Quick Delivery

The company provides just-in-time delivery with its streamlined supply chain.

5 ) Cost saving

We provide long-life, shock-resistant and high reliablity plastic mould parts with

excellent quality and better performance resulting in increased cost saving. Our own

manufacture factory promise you a reasonable price.

6) Attending customers queries promptly

1. the mould surface of cavity and core will be covered with anti corrosive oil.

2. the guide pin and guide bushing will be covered with butter.

3. the mould will be wrapped in plastic film.

4. the mould will be packed in customized wooden case.

5. the wooden case will be strapped with metal bands.

6. some other spare parts will be put into the wooden case together with mould, there are material certificate, mould data

CD, hot sprue , lifting bolt , ejector pin etc.

Production equipments:

Production processing:

|

|

Small Scale Polystyrene Injection Molding Clear Drinking Cups High Precision Images |